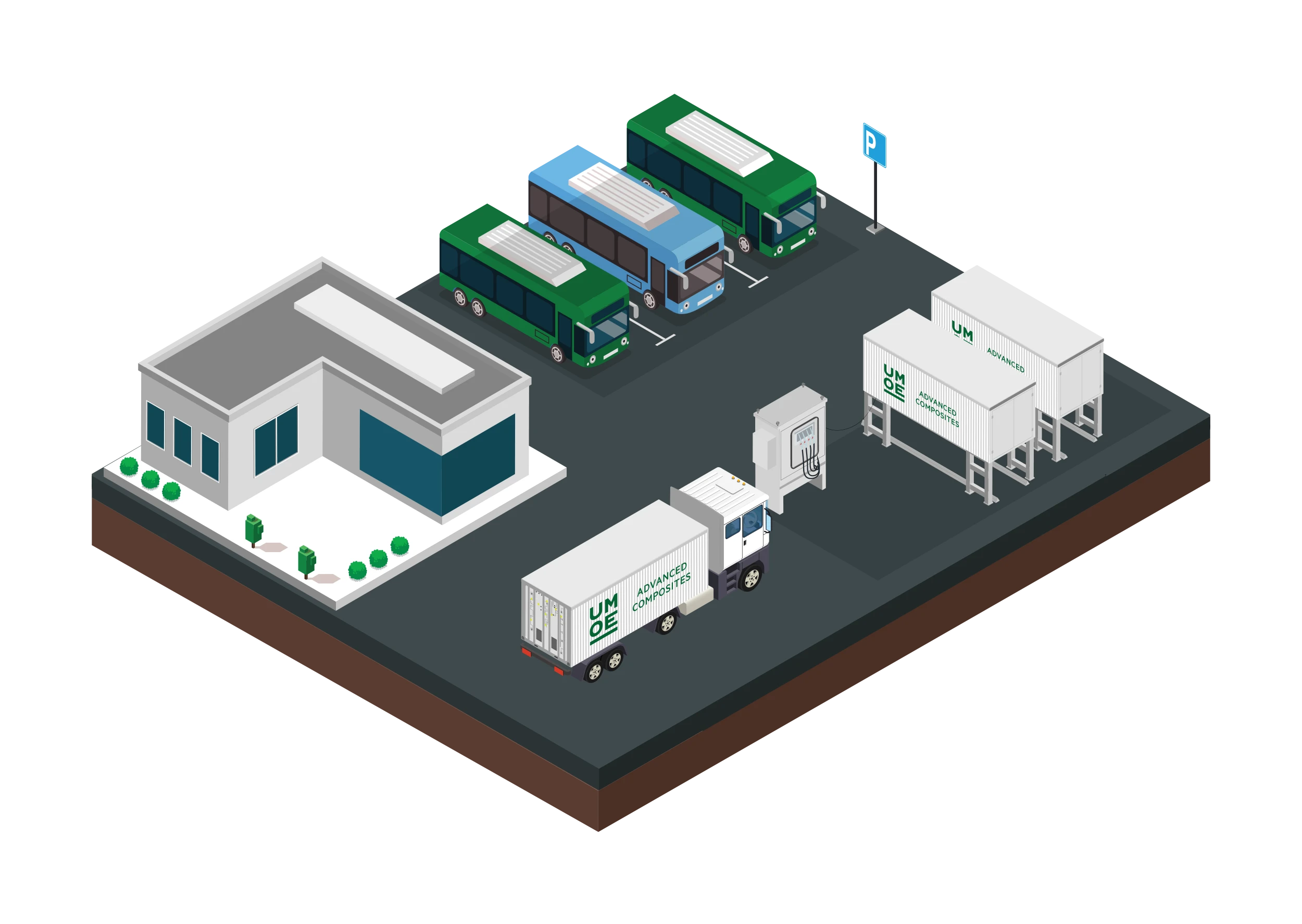

Refueling

UAC can deliver type IV pressure vessels both as containment systems onboard ships and for purpose of transportation of natural gas as cargo onboard container vessels. We can also supply pressure vessels for transportation of CO2.

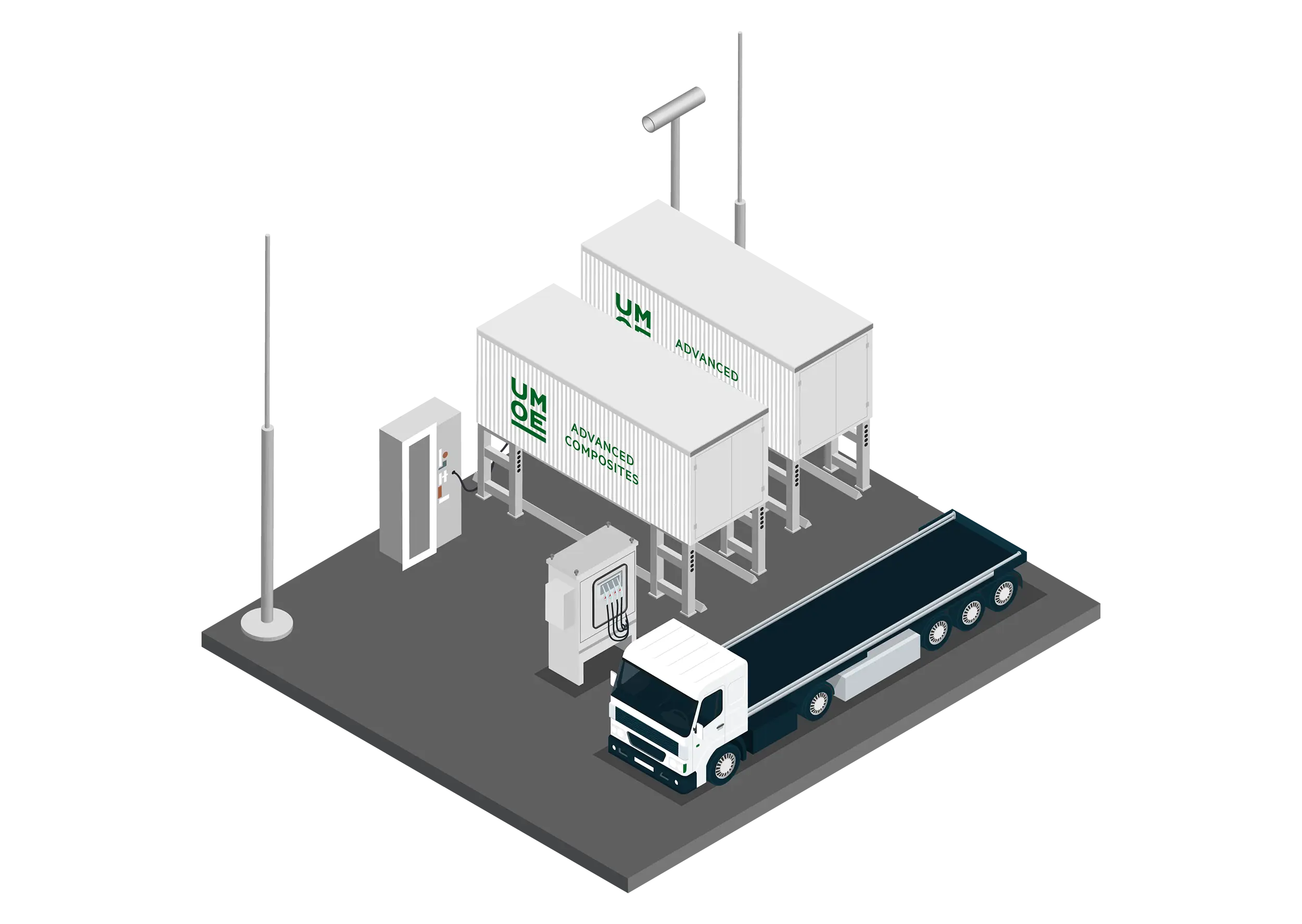

Refueling

UAC can deliver type IV pressure vessels both as containment systems onboard ships and for purpose of transportation of natural gas as cargo onboard container vessels. We can also supply pressure vessels for transportation of CO2.

CNG storage and transportation

Transport of compressed natural gases requires an assessment of the ideal pressure and temperature in order to optimize the CNG ships and the value chain. Generally, higher pressure and lower temperature offer a higher gas density, influencing containment volume and ship size.

Marine CNG will be able to fill the gap for small and medium volumes, and short and intermediate sailing distances. CNG could be most competitive in emerging coastal markets, in inter-regional areas, where pipelines are either uneconomical or technically challenging, and in island states with strong governmental support for economical and/or environmental developments.